Thorsite™ Hybrid AlCrN Coated Burs

Thorsite™ Milling tools have been developed with a new hybrid AlCrN based-coating that is ideal for milling Titanium and Cobalt-Chrome dental materials.

Thorsite™ millings tools are specially designed and processed to provide extended wear and high strength in high-speed machining applications of Titanium and Cobalt-Chrome materials.

Using state of the art coating processes, each tool is engineered with optimum coating adhesion, high thermal shock stability, and is optimal for highly stressed cutting edges.

Thorsite™ Hybrid OPTIMIZED PERFORMANCE Coating

| Technology | Benefit |

| Latest in Etching Technology | Optimized coating adhesion results in high-level reliability when machining titanium and cobalt-chrome dental materials |

| Balancing of residual stress and coating hardness | High thermal shock stability |

| Dual-Layer structure | Increased oxidization resistance |

| High Abrasion-resistance improved hardness | Significantly lengthened tool lifetimes as compared to common high-performance coatings |

| Durable and very smooth surface | Extremely high tool cutting edge-stability |

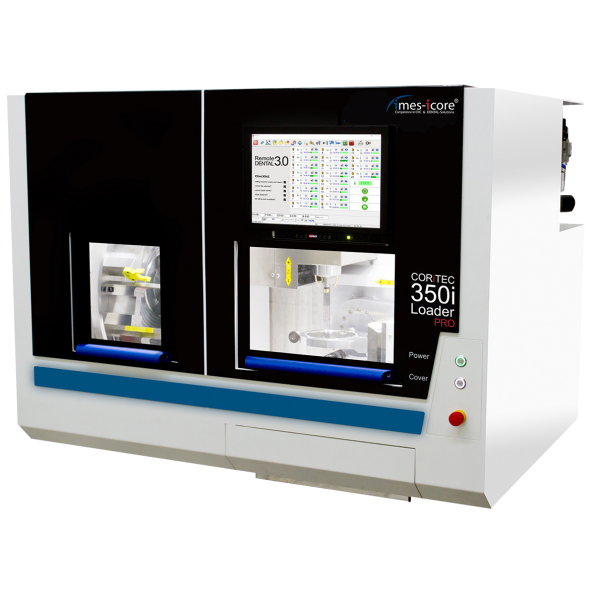

SHOP BY MILLING MACHINE