Sabrenite™ CAD CAM Milling Burs

At RAC, we have developed a new composite Chromium Nitride coating treatment (Sabrenite™ technology) for our burs used in milling PMMA/PEEK materials.

Sabrenite™ is an excellent coating that provides lubricity and superior wear and corrosion resistance. Our Sabrenite™ technology has a very low residual stress, which provides for the best adhesion and ductility. High hardness, low coefficient of friction and the low residual stress of Sabrenite™ combine to resist abrasive and excessive wearing when machining PMMA/PEEK materials. RAC’s Sabrenite™ is an extremely hard, inert, thin film coating that is applied to offer greater temperature resistance when milling PMMA/PEEK materials.

Sabrenite™ is an excellent coating that provides lubricity and superior wear and corrosion resistance. Our Sabrenite™ technology has a very low residual stress, which provides for the best adhesion and ductility. High hardness, low coefficient of friction and the low residual stress of Sabrenite™ combine to resist abrasive and excessive wearing when machining PMMA/PEEK materials. RAC’s Sabrenite™ is an extremely hard, inert, thin film coating that is applied to offer greater temperature resistance when milling PMMA/PEEK materials.

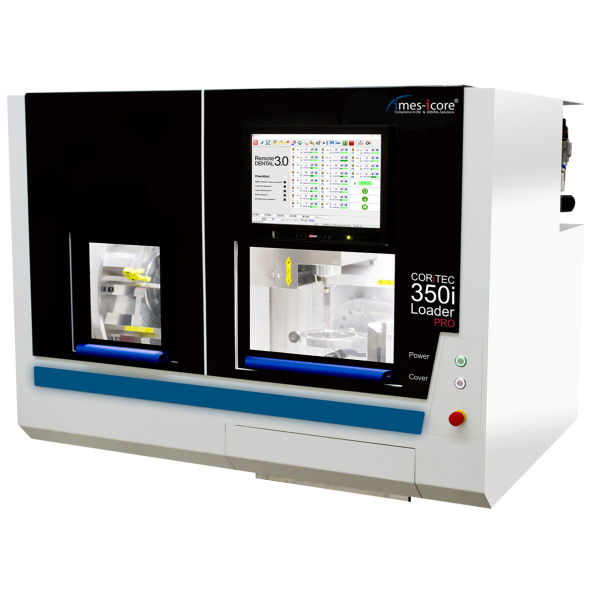

SHOP BY MILLING MACHINE